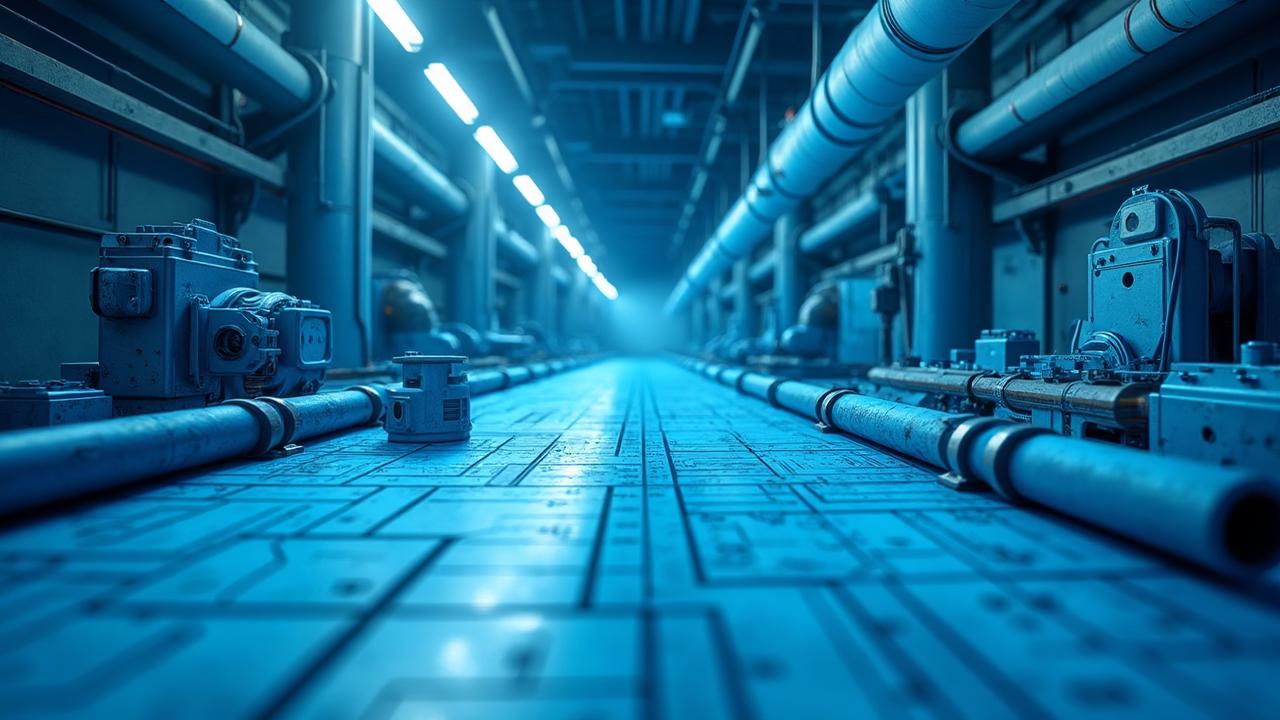

Audits &Optimisation

Insight that drives improvement.

Comprehensive system audits and performance optimisation delivering measurable cost savings.

Book System AuditKEY CAPABILITIES

Performance Audits

Comprehensive system assessments evaluating equipment condition, operational efficiency and compliance. Identify underperforming assets, inefficiencies and opportunities for improvement.

Energy Analysis

Detailed energy consumption analysis with benchmarking against industry standards. Quantify energy waste, model potential savings and prioritise efficiency investments.

Cost Reduction Strategies

Actionable recommendations to reduce operating costs through equipment upgrades, operational adjustments and maintenance optimisation. ROI-focused strategies backed by engineering analysis.

Operational Optimisation

System tuning and control optimisation to improve performance, reduce energy consumption and extend equipment life without capital investment. Practical adjustments for immediate impact.

Refrigerant Transition Planning

Strategic roadmaps for low-GWP refrigerant migration and compliance with phase-down regulations. Assess system compatibility, equipment upgrades and timing to minimise disruption.

Compliance & Risk Assessment

Regulatory compliance audits covering AS/NZS 1677, 5149 and refrigerant regulations. Identify non-conformances, safety risks and liability exposure with corrective action plans.

HOW WE IMPROVEPLANT PERFORMANCE

Audits are only valuable when they lead to action. Our optimisation process is practical, evidence-based and focused on outcomes.

Comprehensive system assessment

Audits examine equipment condition, control strategies, energy use and compliance across the entire system.

Data-driven analysis

Monitoring, benchmarking and engineering analysis are used to quantify inefficiencies and prioritise opportunities.

Practical, implementable recommendations

Findings are translated into clear actions that can be implemented without unnecessary complexity or disruption.

Energy and cost reduction focus

Opportunities are assessed through a lifecycle and ROI lens to ensure improvements deliver tangible value.

Compliance and risk visibility

Audits identify regulatory gaps and safety risks, with clear guidance on corrective actions.

Capability to deliver improvements

Our engineering and delivery teams can design and implement recommended upgrades, ensuring audit outcomes translate into real results.

WHY TRI TECH REFRIGERATION

LET'S MAXIMISE

YOUR EFFICIENCY

Unlock hidden savings and improve performance with a comprehensive system audit