IndustrialHVAC

Performance you can rely on.

Uptime you can plan around.

Industrial environments demand more than comfort cooling. They require stable temperatures, dependable plant performance and service delivery that does not introduce risk. Tri Tech Refrigeration delivers industrial HVAC solutions built on the same engineering discipline, safety focus and lifecycle reliability that underpin our refrigeration heritage.

Request HVAC ServiceKEY CAPABILITIES

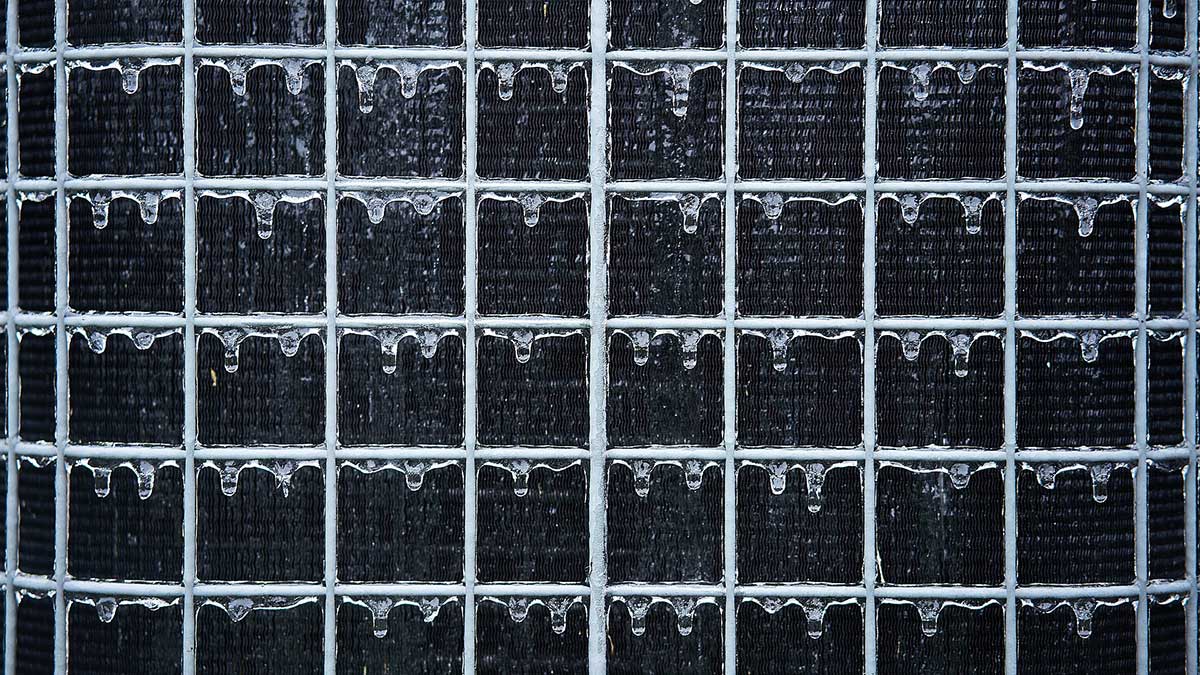

Planned Preventive Maintenance (PPM)

Structured maintenance programs for chillers, AHUs, cooling towers, ventilation systems and associated controls. Maintenance schedules are tailored to site conditions and asset criticality, improving reliability, efficiency and compliance while reducing unplanned failures.

Emergency HVAC Response (24/7)

Rapid response integrated with our national emergency hotline. Fast fault diagnosis, on-site repairs and interim climate control solutions to keep production environments operating safely and within specification.

Controls, BMS & PLC Optimisation

Review and refinement of control logic, setpoints and operating sequences to stabilise performance and reduce energy consumption. Where required, we facilitate BMS integration and migrations to open protocols such as BACnet to reduce vendor lock-in and improve system interoperability.

System Performance Optimisation

System health assessments, efficiency reviews and tuning to improve temperature control, airflow balance and energy performance while extending equipment life.

HVAC Upgrades & Modernisation

Targeted upgrades for ageing HVAC plant, including high-efficiency equipment, updated controls and low-GWP refrigerant integration where applicable. Solutions are designed to improve performance, sustainability and operational resilience without unnecessary disruption.

Compliance Documentation & Asset Registers

Comprehensive asset registers, service records, performance logs and compliance documentation suitable for audits. Clear, traceable service history across every facility, supported by practical recommendations.

HOW WE DELIVERRELIABLE HVAC

Industrial HVAC performance depends on disciplined execution, not promises. Our delivery model is designed to minimise risk, maintain process stability and provide confidence at every stage.

Responsive communication and realistic timelines

From first contact through to job completion, we provide direct communication and clear, achievable timelines. You are kept informed of progress, findings and outcomes, with no ambiguity or surprises.

Structured, process-driven service delivery

All work is carried out using defined service workflows to ensure tasks are completed correctly, documented clearly and aligned with site requirements, safety systems and operational constraints.

Prepared and capable technicians

Our technicians arrive on site prepared, with the tools, parts and expertise required to diagnose and resolve issues efficiently and safely the first time.

Safety, compliance and site discipline

Work is performed in accordance with strict WHS, site safety and compliance requirements, protecting your people, assets and production environment.

Clear reporting and operational handover

Every visit is supported by clear service reporting, performance observations and practical recommendations, providing traceability for audits and confidence for operations teams.

Consistent execution across every engagement

Whether planned maintenance, optimisation work or emergency response, you receive the same professional conduct, respect for process-critical environments and dependable delivery at every visit.

WHY TRI TECH REFRIGERATION

KEEP YOUR PLANT

RUNNING RELIABLY

Proactive HVAC maintenance and disciplined service delivery keep your production environment stable, compliant and energy-efficient.