Servicing &Maintenance

Proactive care. Peak performance.

Comprehensive scheduled maintenance and preventive care ensuring peak system efficiency year-round.

Get Maintenance QuoteKEY CAPABILITIES

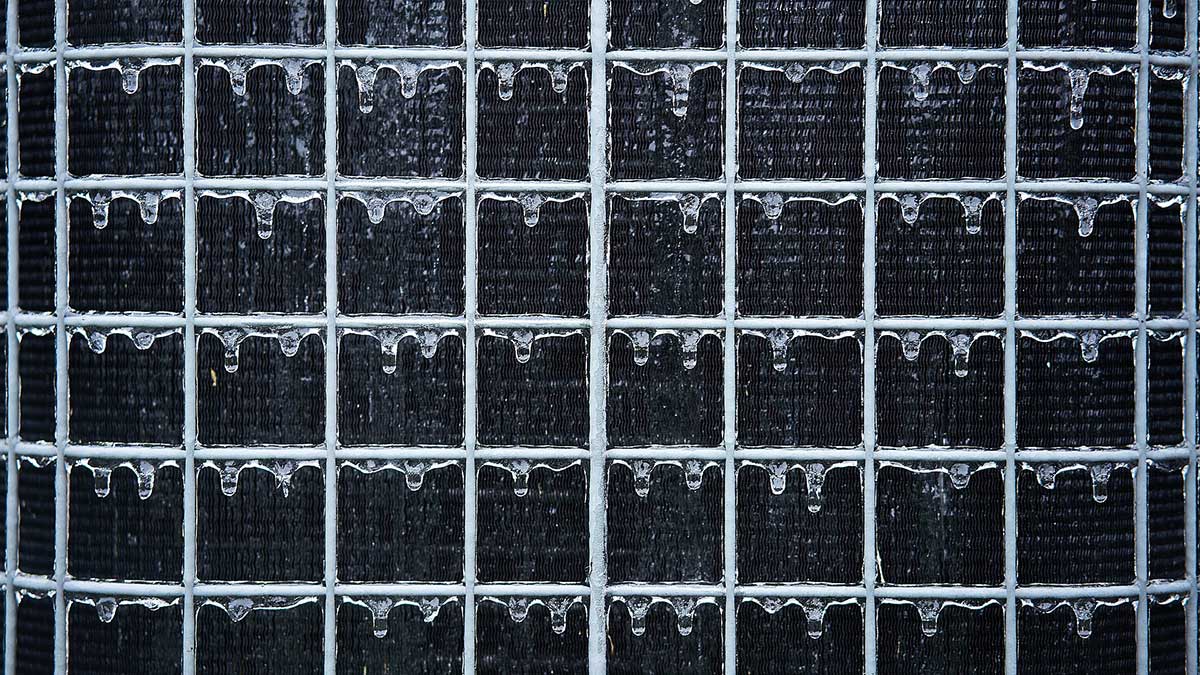

Preventive Maintenance

Scheduled service programs tailored to your equipment and operational demands. Advanced diagnostics, proactive fault detection and documented service records to maximise uptime and asset life.

Compressor Overhauls

Specialist overhaul services for industrial compressors including screw, reciprocating and centrifugal types. In-house rebuild capability with OEM-trained technicians and genuine parts.

Spare Parts & Consumables

Extensive inventory of refrigeration components, consumables and critical spares. Rapid dispatch across Australia to minimise downtime and keep your plant operational.

Equipment Leasing

Temporary refrigeration equipment available for emergency situations, planned shutdowns or seasonal capacity increases. Rapid deployment with full technical support.

Remote Monitoring & Diagnostics

Proactive system monitoring with remote fault diagnosis and troubleshooting capability. Early detection of performance issues to prevent costly breakdowns and optimise efficiency.

Compliance Auditing & Reporting

Detailed service records, asset registers and compliance documentation to meet regulatory requirements. Full traceability and audit-ready reporting for every facility.

HOW WE KEEPSYSTEMS RUNNING

Effective maintenance is proactive, data-driven and consistent. Our service approach is designed to reduce unplanned downtime and protect asset life.

Site-specific maintenance programs

Service schedules are tailored to equipment type, operating conditions and criticality, rather than generic intervals.

Early fault detection and intervention

Advanced diagnostics and condition monitoring are used to identify emerging issues before they result in failures.

Skilled technicians and specialist capability

Our technicians are trained across a wide range of industrial refrigeration plant, supported by in-house overhaul and specialist services.

Rapid access to parts and equipment

Extensive spare parts inventory and equipment hire capability reduce downtime during planned and unplanned events.

Clear documentation and compliance tracking

Every visit is documented with service records, asset updates and compliance information suitable for audits and operational review.

Integration with emergency response

Maintenance programs are supported by our 24/7 breakdown response network, ensuring continuity of support when it matters most.

WHY TRI TECH REFRIGERATION

LET'S KEEP IT

RUNNING

Keep your systems running at peak performance with our comprehensive maintenance programs